Hop Up Platforms

A leader in hop up platforms

About our Hop up platforms

Semmco has been designing and manufacturing a range of access steps and platforms since 1993. These steps and platforms enable engineers to easily and efficiently access and carry out their overhaul and maintenance activities on different areas of aircraft and trains, without over-reaching.

You are currently filtering to show products RESET

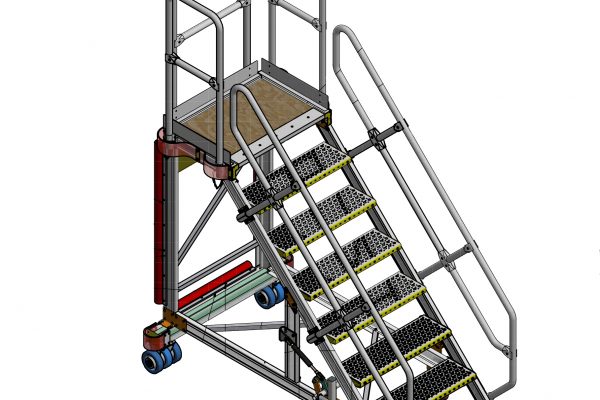

HOP UP Towable H1.2m Belly Steps

Part No: 812.002.10

Aircraft belly step access Hop UP platform H1.2 X W0.65 X L0.8. Easy to position and manoeuvre in and around aircraft on the line or hangar for safe access into Belly access hatches. Incorporating a robust

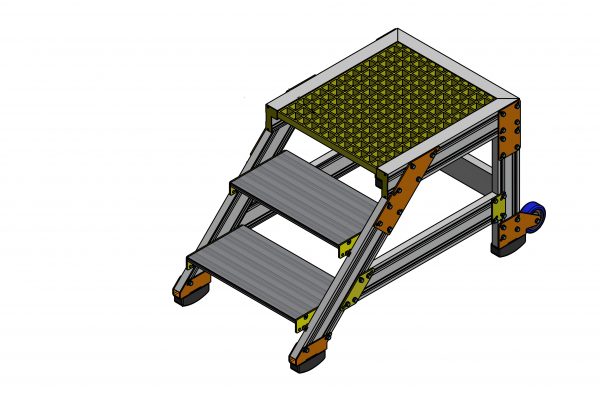

HOP UP General Engine Access Platform 3 steps H0.76m

Part No: 812.002.13

HOP UP General Engine Access Platform with 3 steps and working platform H0.76m X L1.3m X W0.6m.Easy to position in and around engines for maintenance and assembly. With a robust lightweight aluminium

HOP UP General Engine Access Platform 4 Step H1.0m

Part No: 812.002.12

HOP UP General Engine Access Platform with 4 steps and working platform H1.0m X L1.6m X W0.6mEasy to position in and around engines for maintenance and assembly. With a robust lightweight aluminium construction

HOP UP General Engine Access Platform 7 Step H1.74m

Part No: 812.002.14

HOP UP General Engine Access Platform 7 Step H1.74m X L2.25m X W0.6mEasy to position and manoeuvre in and around engines incorporating a robust lightweight aluminium construction for ease of manoeuvring

HOP UP Step for A320 Stab Bay Access

Part No: 812.002.17

HOP UP Step H0.50 X L0.75 X W0.75m Designed for use with fixed height maintenance steps H2.25m 812.225.01 Providing easy step access to stab bay incorporating slip resistant aluminium platform

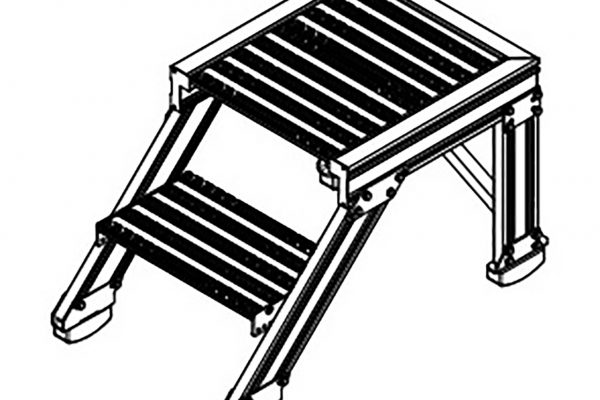

HOP UP Working Platform/Step H0.5m

Part No: 812.002.24

HOP UP Working Platform/step H0.50m X L0.54m X W0.50mDesigned for that extra reach incorporating slip resistant “X-Cut” aluminium step & platform with solid rubber feet pads for anti-slip.Ease

HOP UP Steps 0.4m for use with A320 Fan Cowl Platforms

Part No: 812.002.04

Simple safe easy to use “Hop UP” step designed for use with A320 engine fan cowl steps H0.4 X L0.73 X W0.50.Incorporates location pins which locate & lock on to the fan cowl platform for

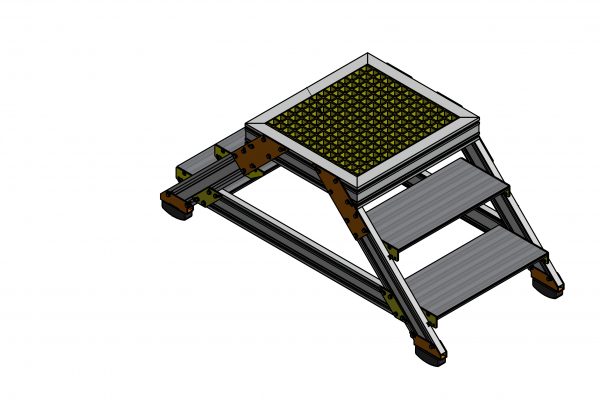

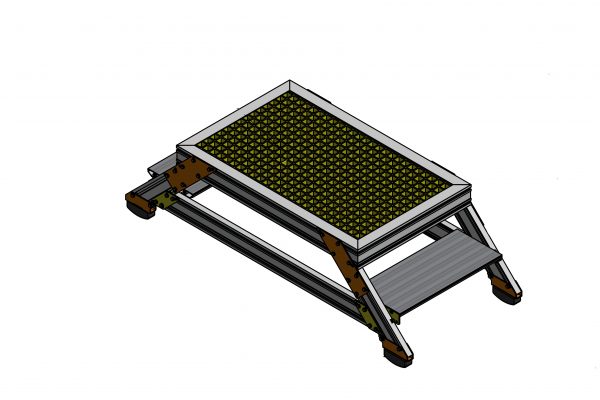

HOP UP Working Platform 3 Step GRP Platform

Part No: 812.002.26

HOP UP Working Platform - 3 steps and GRP platform H0.60m x L0.60m x W0.60m.Designed for that extra reach incorporating slip resistant aluminium stair treads open mesh GRP platform.Using front castors

HOP UP Rail Bridging Platform Double Sided Step

Part No: 812.002.27

HOP UP Rail Bridging Platform step H0.60m x L0.60m x W0.60m.Designed for access either side of the platform for that extra reach, incorporating slip resistant aluminium stair treads and an open mesh GRP

HOP UP Bridging Platform Large GRP 2 Step for Pit Access

Part No: 812.002.28

HOP UP Bridging Platform/step H0.46m x L1.0m x W0.65m.Designed for rail depot pit access from either side of the platform for that extra reach, incorporating slip resistant aluminium stair treads large

About our Hop Up platforms

About our Hop Up platforms

The Hop Up platforms from Semmco can be used independently or alongside other access platforms to increase the level of accessibility. Consequently, the Hop Up range suitable for use with aircraft includes simple access steps such as the Hop Up Working Platform, the Hop Up Step with Handrails and the Hop Up Cabin Interior Steps, to more elaborate fixed height, towable, engineers maintenance steps for areas such as fan and core cowl access or hydraulic and stab bay access. Semmco also supplies a simple Hop Up Working Platform for use with trains. All our platforms incorporate the high quality manufacturing and materials synonymous with Semmco.

Hop Up Working Platform/Step

https://semmco.com/products/hop-up-working-platform-step-2/

This simple, but extremely useful Hop Up Working Platform can be easily positioned to provide additional height quickly. It has a height of 0.5m and has slip resistant tread and solid rubber feet for extra safety and prevent the platform moving or those using it slipping.

Made from aluminium it is lightweight but robust and easy to manoeuvre.

Hop Up Steps for A320 Stab Bay Access

https://semmco.com/products/hop-up-step-for-a320-stab-bay-access-812-225-01/

These hop up steps provide easy access to the A320 Stab Bay. They have been ergonomically designed to make them very easy to use, incorporating slip resistant aluminium platform tread. They can be used on their own on in conjunction with the Fixed Height Maintenance Steps, providing a little bit more height to prevent over-reaching.

Hop Up General Engine Access Platforms

https://semmco.com/products/hop-up-general-engine-access-platform-3-steps/

https://semmco.com/products/hop-up-general-engine-access-platform-4-step/

https://semmco.com/products/hop-up-engine-strip-build-h1-74m/

This range of Hop Up General Engine Access Platforms provide different height levels depending on the customer’s requirements. Each platform is made from lightweight aluminium and so they are easy to manoeuvre and position in and around engines. They are fitted with supporting handrails and have slip-resistant aluminium stair tread. If necessary, they are fitted with ‘soft’ padding to protect the engine.

Hop Up Towable Belly Steps

https://semmco.com/products/hop-up-towable-h1-2m-%c2%96-belly-steps/

The Hop Up Towable Belly Steps are 1.2m high and can be easily moved into position in and around the hangar or on the line. They incorporate a lightweight steel chassis and lightweight aluminium and the front chassis has two suspension mounted wheels to make towing easy. This Hop Up provides safe access into belly access hatches and the stair treads are manufactured from slip resistant aluminium for added safety.

Hop Up Working Platform 3 Step GRP Platform

https://semmco.com/products/hop-up-%c2%96-working-platform-step-%c2%96-grp-platform-no-hand-rails/

The Hop Up Working Platform 3 Step GRP Platform has been designed for use with trains to enable extra reach but in a safe way. The platform is 0.6m high and incorporates slip resistant aluminium stair treads and an open mesh GRP platform to prevent the engineers slipping while using the Hop Up. The platform can be tilted to roll into position and is help firmly in place with solid rubber feet pads.

Hop Up Bridging Platform for Pit Access

This platform is designed for rail depot pit access from either side of the platform to provide extra reach, safely. The platform is 0.46m high and incorporates slip resistant aluminium stair treads and a large working platform with open mesh GRP. Solid rubber feet prevent the platform from slipping once in position.

Our hop-up platform applications

All our hop up platforms are designed to provide that ‘extra’ height when just a little height is required. It is extremely important that maintenance engineers can carry out their work safety and over-reaching can put the engineers at risk. Therefore, hop up platforms and steps overcome this issue and are simple and lightweight to manoeuvre into position. They can make a maintenance task much easier very quickly.

For engineers carrying out maintenance on aircraft, our range of hop up platforms and steps can help them access various areas of the aircraft including the fan cowl, stab bay, avionics bays and general engine access.

Why Choose Semmco?

Semmco has been designing and manufacturing access platforms and steps for use in the aviation and rail industries for more than 30 years and is recognised the world over for producing a high quality product, manufactured to exceptional standards that lasts for many, many years.

While the company has a range of standard products used extensively by aircraft and rail maintenance companies, Semmco also works closely with its customers to design and manufacture bespoke access platforms to meet very specific requirements. For some of our aircraft customers, we have developed, manufactured and installed, fixed access platforms that are used when extensive maintenance has to be carried out.

Our Service Packages are designed to provide ongoing support and maintenance for our products once they have been supplied to the customer. This support could include Semmco Engineers installing and commissioning our products and providing instruction on how to use our products correctly. Some of our smaller items, such as our hop up platforms, are supplied pre-built and can be put into service immediately.

https://semmco.com/product-support/

Our range of hop up platforms and steps are used independently or in conjunction with some of our other access platforms, bespoke access platforms and aircraft steps.

FAQs

What are your hop up steps manufactured from?

Our hop up steps are generally manufactured from aluminium but our towable hop up steps have a steel chassis for extra strength.

How do you fix the hop up platforms in place to prevent them moving?

Most of our hop ups are fitted with solid rubber feet pads that prevent the platforms from moving. Some are fitted with over centre castor jacks that lock the wheels once the platform is in place.

Do your hop up platforms have non-slip tread?

Yes, the stairs are manufactured from slip resistant aluminium tread and the working platforms are either manufactured from phenolic wood or open mesh GRP.

Are the hop up platforms easy to manoeuvre?

Yes, they are lightweight and are fitted with castor wheels so they can be tilted and rolled into positon or towed via the towing hook.

Please use copyscape compare to ensure that the new content is less than 10% similar to any other content on the page. https://www.copyscape.com/compare.php